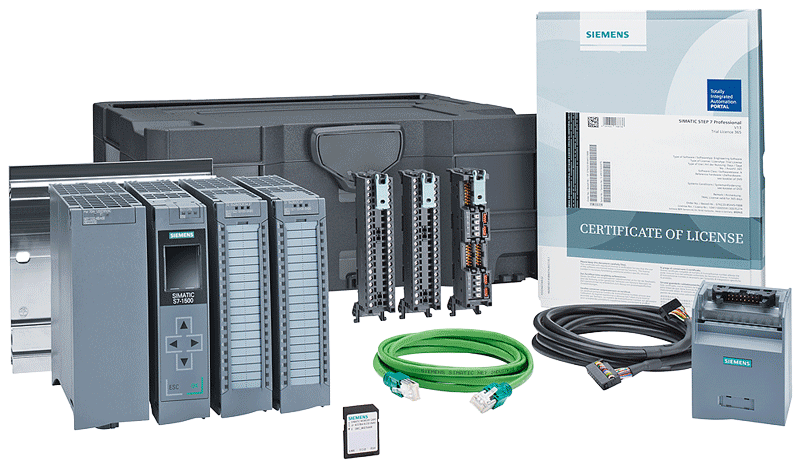

Plc siemens

PLC Programming (Programmable Logic Controller Programming) involves creating and implementing control logic for industrial automation systems. PLCs are specialized computers used to monitor inputs, make decisions based on logic, and control outputs to automate machinery or processes.

Steps in PLC Programming

1. Define System Requirements

- Understand the process or machinery to be automated.

- Identify inputs (sensors, switches) and outputs (motors, lights, solenoids).

- Define operational requirements, safety measures, and control logic.

2. Develop a Logic Flow Diagram

- Outline the process using diagrams like flowcharts or SFCs.

- Break down operations into logical steps or sequences.

3. Write the PLC Program

- Choose the appropriate programming language (e.g., Ladder Logic for simple tasks).

- Implement logic for tasks like:

- On/Off Control: Start/stop operations.

- Timing Functions: Delays or intervals using timers.

- Counting Functions: Count inputs/events using counters.

- Mathematical Operations: Perform calculations if needed.

4. Simulate the Program

- Use PLC simulation software to test the program virtually.

- Verify the logic and ensure all possible scenarios are accounted for.

5. Download the Program to the PLC

- Transfer the program to the PLC using programming software.

- Examples: Siemens TIA Portal, Allen-Bradley RSLogix, Schneider Electric EcoStruxure.

6. Test and Debug

- Test the program on actual hardware in a controlled environment.

- Debug issues such as incorrect logic, timing errors, or unresponsive inputs/outputs.

7. Monitor and Optimize

- Monitor the system during operation.

- Refine the program for efficiency or adapt it to new requirements.

Common PLC Applications

- Manufacturing:

- Assembly lines, robotic arms, and quality control systems.

- Process Control:

- Oil refineries, chemical plants, and water treatment facilities.

- Building Automation:

- HVAC systems, lighting controls, and security systems.

- Transportation:

- Conveyor belts, elevators, and automated guided vehicles (AGVs).